A general term for injection processes that use special chemical solutions to improve oil recovery, remove formation damage, clean blocked perforations or formation layers, reduce or inhibit corrosion, upgrade crude oil, or address crude oil flow-assurance issues. Injection can be administered continuously, in batches, in injection wells, or at times in production wells.

Pages

Custom Search

JOB VACANCY IN BALIKPAPAN

Sunday, February 22, 2015

Saturday, February 21, 2015

AutoCAD Tool Palettes – Cable Tray, Tubing Tray and fitting included attribute for 3d models

|

| STRAIGHT CABLE TRAY USE AUTO LISP |

|

| SAMPLE ASSEMBLING WITH FITTING TRAYS |

Adding and

editing components becomes easier in AutoCAD with tool palettes. The tool

palettes contain blocks. With the parameter action Polar Stretch, you can just

type the length you desire and AutoCAD will stretch the tray to that length.

Furthermore, you can rotate the block before you place it. In my opinion the

tool palettes are user friendly. Even a novice can use them. Moreover you can

insert blocks into your drawing with drag and drop. It is easy to access from

tool palettes.

Open and close

the tool palette by pressing CTRL+3. You can auto-hide the tool palette in the

vertical blue area of the tool palette, simply click on the symbol <>I.

By doing that, you leave more space in the drawing area.

Friday, February 20, 2015

ITEM SAFETY INSPECTION CHECK FOR WELDING MACHINE :

- Spark arrestor

- Insulation system of exhaust

- Electrical/ welding cable connection

- ESD. system

- Socket/ Power supply connector

- Electric cable insulation

- Cable grounding system

- Ampere indicator

- Safety guarding system

- ELCB (30 mA) installed

- Battery covered

- Engine and fuel system leaks

- Lifting point/ pad eye condition (certified)

- Fire extinguisher ( stand by when use)

- General condition

- Inspection sticker

ITEM SAFETY INSPECTION CHECK FOR SCAFFOLDING:

GUARD RAILS

Securely fastened, 90 cm to 120 cm high, Gap between toe board and first

rail not more or <76 cm="" o:p="">

TOE BOARDS

All rounds protection against objects falling, Minimum high 15 cm.

Monday, February 16, 2015

Wednesday, February 11, 2015

Wednesday, February 4, 2015

Thursday, May 2, 2013

XYR 6000 Wireless Universal I/O Transmitter – Multi AI/DI/DO

Thursday, April 18, 2013

Exploration and Drilling

When 3D seismic has been completed, it is time to drill the well. Normally dedicated drilling rigs either on mobile onshore units or offshore floating rigs are used. Larger production platforms may also have their own production drilling equipment.

The main components of the drilling rig are the Derrick, Floor, Drawworks, Drive and Mud Handling. The control and power can be hydraulic or electric.

Earlier pictures of Drillers and Roughnecks working with rotary tables (bottom drives) are now replaced with top drive and semi automated pipe handling on larger installations. The hydraulic or electric top drive hangs from the derrick crown and gives pressure and rotational torque to the drill string. The whole assembly is controlled by the drawworks.

The Drill String is assembled from pipe segments about 30 meters (100 feet) long normally with conical inside threads at one end and outside at the other. As each 30 meter segment is drilled, the drive is disconnected and a new pipe segment inserted in the string. A cone bit is used to dig into the rock. Different cones are used for different types of rock and at different stages of the well. The picture shows roller

cones with inserts (on the left); other bits are PDC (polycrystalline diamond compact, on the right) and Diamond Impregnated.

Photo: Kingdream PLC

Crude oil and Natural gas

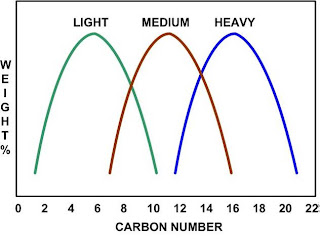

Crude Oil is a complex mixture consisting of up to 200 or more different organic compounds, mostly hydrocarbons. Different crude contain different combinations and concentrations of these various compounds. The API (American petroleum institute) gravity of a particular crude is merely a measure of its specific gravity, or density.

Monday, April 15, 2013

Saturday, April 13, 2013

Friday, April 12, 2013

Thursday, April 11, 2013

Model 1500 Thermoelectric Generators

Tuesday, April 9, 2013

Scanner® 2000

The NuFlo Scanner 2000 microEFM packs the gas and steam measurement capabilities traditionally found in large flow computers into a compact, low-power instrument.

Monday, April 8, 2013

Honeywell Smart Multivariable Transmitter/ Multivariable Analog Interface for Fuel Flow Measurement Flow Measurement in the Oil and Gas Industry

Problem: A major gas plant was using

a Moore 4-20 ma indicator/integrator

to obtain totals for fuel flows. Total

flow tabulation was labor intensive.

A customer was using a Moore

indicator/integrator to obtain total flows from a

Smart Multivariable Transmitter (SMV3000)

measuring a fuel flow. The Moore indicator

could integrate the SMV flow signal in the

analog mode and totalize the flow over time.

Unfortunately, the flow had to be totalized

manually at the end of each day, week, and

month. A method was needed to eliminate

remove manual calculations.

Recently, the plant underwent a detailed

study to identify areas where automation could

result in significant cost savings to the plant .

Solution: The Honeywell Smart

Multivariable Transmitter used with

the Multivariable Analog Interface

and the VPR 100 Video Recorder

used for automatic totalization.

The plant needed an inexpensive,

simple method for measuring and recording

fuel flows over several time periods. The Smart

Multivariable Transmitter (SMV3000) provides

measurement of differential pressure across a

primary flow element such as an orifice or pitot

tube, a process (static) pressure measurement

and a process temperature using either an RTD

or thermocouple. As the fourth process

variable, the SMV3000 provides a compensated

flow measurement based on the first three

process variables.

The Multivariable Analog Interface

(MVA141) manufactured by Vektron Corp.

allows all process variables to be transmitt

a Moore 4-20 ma indicator/integrator

to obtain totals for fuel flows. Total

flow tabulation was labor intensive.

A customer was using a Moore

indicator/integrator to obtain total flows from a

Smart Multivariable Transmitter (SMV3000)

measuring a fuel flow. The Moore indicator

could integrate the SMV flow signal in the

analog mode and totalize the flow over time.

Unfortunately, the flow had to be totalized

manually at the end of each day, week, and

month. A method was needed to eliminate

remove manual calculations.

Recently, the plant underwent a detailed

study to identify areas where automation could

result in significant cost savings to the plant .

Solution: The Honeywell Smart

Multivariable Transmitter used with

the Multivariable Analog Interface

and the VPR 100 Video Recorder

used for automatic totalization.

The plant needed an inexpensive,

simple method for measuring and recording

fuel flows over several time periods. The Smart

Multivariable Transmitter (SMV3000) provides

measurement of differential pressure across a

primary flow element such as an orifice or pitot

tube, a process (static) pressure measurement

and a process temperature using either an RTD

or thermocouple. As the fourth process

variable, the SMV3000 provides a compensated

flow measurement based on the first three

process variables.

The Multivariable Analog Interface

(MVA141) manufactured by Vektron Corp.

allows all process variables to be transmitt

Technip awarded subsea contract for the Hadrian South development in the Gulf of Mexico

Technip has been awarded a contract by Exxon Mobil Corporation for subsea equipment on the Hadrian South natural gas project in the Gulf of Mexico in approximately 7,500 feet (2,300 meters) of water.

The project consists of a subsea tie-back to the planned Anadarko operated spar platform, Lucius(1).

The contract covers:

- project management, procurement and installation of two 7-mile long flowlines(2) and associated jumpers

- installation of a 9-mile umbilical(3), associated foundation and flying leads

- pre-commissioning.

Technip’s operating center in Houston, Texas, will execute the contract. The flowlines will be welded at Technip’s spoolbase located in Mobile, Alabama. The Deep Blue, a deepwater pipelay vessel from the Technip fleet will install the subsea equipment in 2013.

(1) The Lucius Spar hull is currently being built in Technip’s Pori yard in Finland.

(2) Flowline: a pipe, laid on the seabed, which allows the transportation of oil/gas production or injection of fluids. Its length can vary from a few hundred meters to several kilometers.

(3) Umbilical: an assembly of steel tubes and/or thermoplastic hoses which can also include electrical cables or optic fibres used to control subsea structures from a platform or a vessel.

Technip is a world leader in project management, engineering and construction for the energy industry.

From the deepest Subsea oil & gas developments to the largest and most complex Offshore and Onshore infrastructures, our 30,000 people are constantly offering the best solutions and most innovative technologies to meet the world’s energy challenges.

Present in 48 countries, Technip has state-of-the-art industrial assets on all continents and operates a fleet of specialized vessels for pipeline installation and subsea construction.

From the deepest Subsea oil & gas developments to the largest and most complex Offshore and Onshore infrastructures, our 30,000 people are constantly offering the best solutions and most innovative technologies to meet the world’s energy challenges.

Present in 48 countries, Technip has state-of-the-art industrial assets on all continents and operates a fleet of specialized vessels for pipeline installation and subsea construction.

Investor and Analyst Relations

Kimberly Stewart: Tel. + 33 (0)1 47 78 66 74 kstewart@technip.com

Apollinaire Vandier: Tel. + 33 (0)1 47 78 60 74 avandier@technip.com

Public Relations

Christophe Bélorgeot: Tél. +33 (0)1 47 78 39 92

Floriane Lassalle-Massip: Tél. + 33 (0)1 47 78 32 79 press@technip.com

Group website

Technip shares are listed on the NYSE Euronext Paris exchange and the USA over-the-counter (OTC) market as an American Depositary Receipt (ADR: TKPPK).

Subscribe to:

Posts (Atom)